Manufacturing Plants: The New Normal

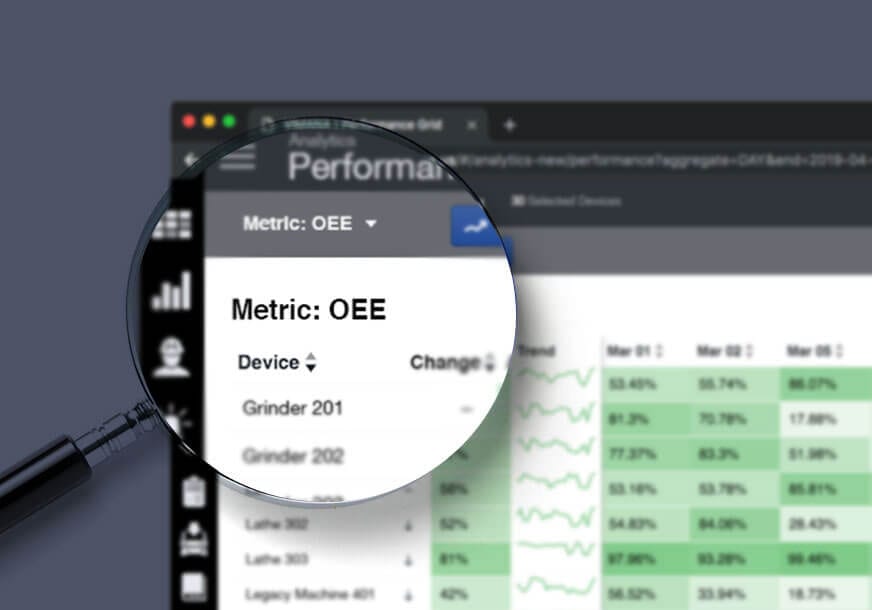

Manufacturers have always prioritized quality, efficiency, and productivity, relying on human capital to produce products that meet customer demand. Some innovative plants have invested in Industry 4.0 technology, including connecting CNC machine tools, industrial automation, 3D printing, and manufacturing analytics, but it has been far from ubiquitous. In the new normal, this must change. Managing through the […]

Manufacturing Plants: The New Normal Read More »