THE INDUSTRIES WE SERVE

We specialize in capturing, analyzing, and visualizing data to help manufacturers increase productivity and profitability.

AEROSPACE & DEFENSE

Trusted by Customers and Partners Recognized by Industry Analysts

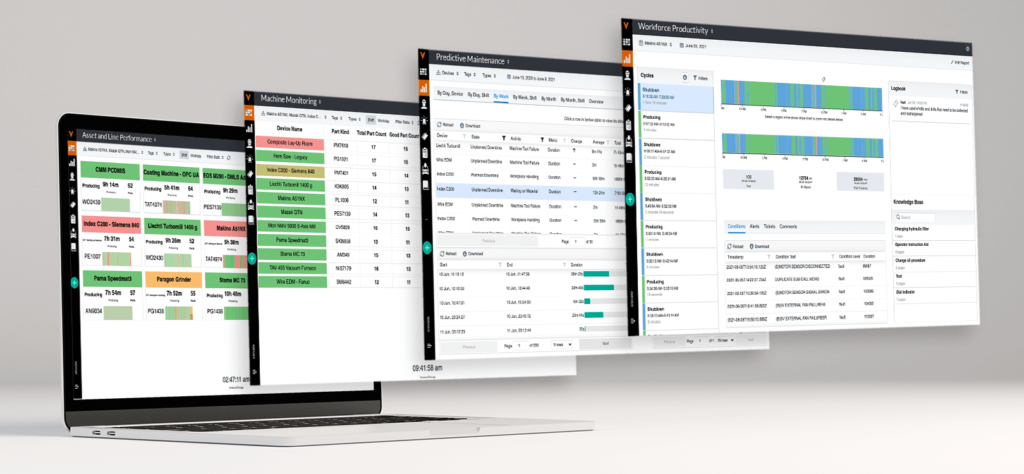

Unlock Smart Manufacturing Excellence with VIMANA Elevate

VIMANA Elevate gives manufacturers real-time visibility into machine and operator performance—so teams can spot issues faster, drive efficiency, and make smarter decisions on the shop floor.

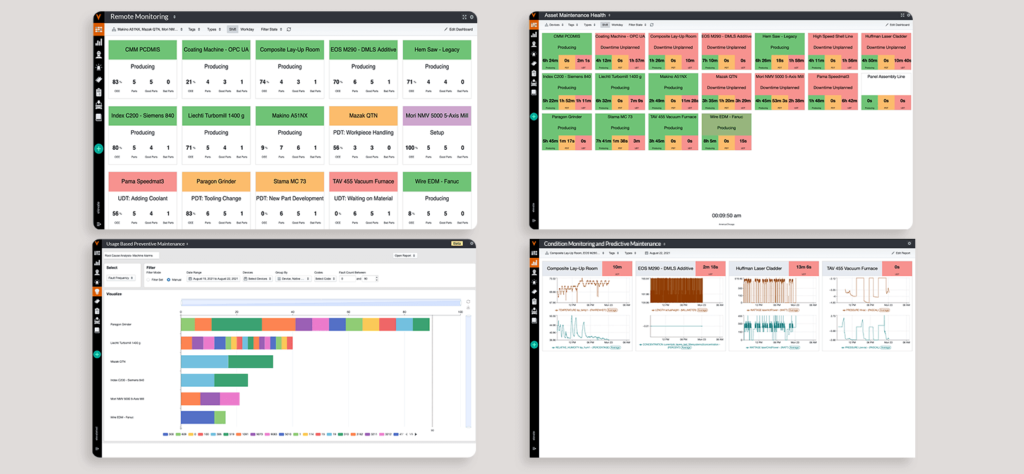

VIMANA’s Industrial IoT Solutions Power Use Cases in Minutes

Smart Manufacturing:

Driving Efficiency and Flexibility

Predictive Maintenance for Connected Products:

Improving Service Delivery and Growing Revenue

VIMANA: WHERE EVERYTHING IS SIMPLE, MODULAR, AND SCALABLE

Industrial IOT Platform

Manufacturing Analytics Applications

Why VIMANA

VIMANA Accelerates Insights. Performance Improvement. ROI.

Ready-to-use modern advanced analytics. Customizable visualizations, analytics applications, and use cases. Speed value. Minimize the need for specialized resources.

We Specialize in Data Analytics for Manufacturers.

We have the expertise and technology to solve your specific problems with purpose-built analytics solutions for manufacturing operations and equipment maintenance.

We Build Data That Works.

We know how to connect to everything. Building trusted data for predictive analytics and deeper insights to optimize processes and increase profitability.

Simple, Scalable, and Affordable.

Software that is easy to implement, use and scale. Buy what you need with modular solutions. No development costs. Decreased operational costs. Lower TCO.

Ecosystem Integration. Deliver Your Connected Factory.

Quickly integrate your existing applications and systems to enrich analytics data and automate workflows and processes from analytics to execution.

Services that Ensure Your Success.

We stay with you each step of the way with end-to-end support from implementation and adoption to improved performance and continuous improvement.