OEM Manufacturers, resellers, and distributors see the opportunity to drive revenue growth and enhance customer experience with products and services enabled by IoT Connected products, data, analytics platforms, and APIs. Savvy industrial businesses are gaining competitive advantage by integrating smart technologies in their products and providing digital and Industry 4.0 solutions out-of-the-box.

The Go-To-Market Value Proposition

IoT Connected Products and analytics platforms provide AI-driven decision support that enables organizations to:

- Enhance customer satisfaction by optimizing field service delivery and support while driving cost efficiencies and productivity from their service teams.

- End-users realize improved uptime, availability, and can maximize the useful life of their equipment.

- Service teams see increased productivity from technicians, better work planning and scheduling, and improved spare parts management and deliver lower costs to serve with labor, parts, and process efficiencies.

-

Increase predictable revenue streams and customer value by transitioning to service-based models and offerings.

- Expand aftermarket services with maintenance subscription packages, support, training, and consulting services.

- Drive sales of product upgrades, replacements, reconditioning, and parts.

- Deliver outcome-based pricing and revenue models based on use and service.

- Current Capability Gaps in Some IoT Connected Product Solutions

- Providers lack a deep understanding of industrial assets/processes and the expertise to collect, cleanse, prepare, and enrich the data for analytics.

- Few platforms provide domain-driven, out-of-the-box capabilities for field service management, asset performance management, and predictive maintenance that deliver rapid business outcomes.

- Many solutions are costly, time-consuming to implement, and resource-intensive to build and maintain.

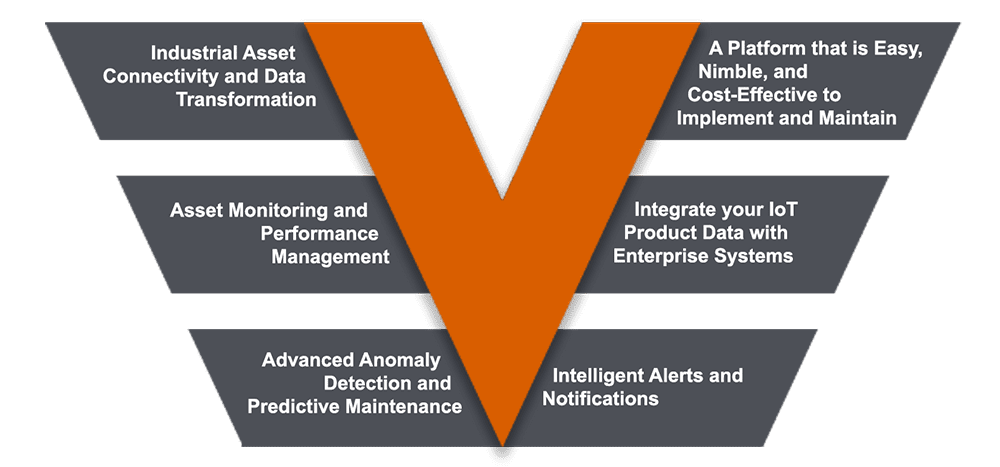

6 “Must-Have” IoT Connected Product Platform Capabilities

- Industrial Asset Connectivity and Data Transformation:

The software must address data ingestion, preparation, contextualization, and build the data foundation for advanced analytics. This accurate and meaningful data collection relies on expertise in industrial assets and manufacturing processes with a deep understanding of connectivity, data architecture, industry standards, and the data pipeline.

- Asset Monitoring and Performance Management:

The solution should provide out-of-the-box, next-generation analytics for IoT Connected Product monitoring and performance management. With mobile access to pre-built, customizable dashboards and reports, technicians and managers have visibility to the real-time status of machine performance, conditions, environment, product operation, and usage across the globe. Field Service teams can quickly identify machines and components requiring repair, downtime duration, and diagnose the root causes of failures to prioritize and understand the actions needed.

- Advanced Anomaly Detection and Predictive Maintenance:

The platform capabilities should include advanced analytics using domain-specific asset models and algorithms for advanced anomaly detection, ML, and AI, delivering predictive and prescriptive insights to field service, business leaders, and end-users. Real-time and historical data reveals patterns and trends in critical parameters providing the knowledge to implement preventative maintenance based on conditions and use. Anomaly detection triggers early warnings of conditions out of tolerance and product and part failures before they occur. Predictive maintenance reduces unplanned downtime, enables more efficient scheduling of repairs and spare part management.

- Intelligent Alerts and Notifications:

Immediately alert stakeholders (technicians, service managers, business leaders and customers) of changes in asset performance metrics, health, and conditions outside normal thresholds or trigger opportunities for product or services sales.

- Integrate your IoT Product Data with Enterprise Systems:

The solution should provide software and tools, including APIs, connectors, adapters to integrate IoT Connected Product data with enterprise systems (MES, Work Order Systems, FSM, EAM, ERP, CRM) to streamline workflows and processes.

- A Platform that is Easy, Nimble, and Cost-Effective to Implement and Maintain:

A platform with flexible, scalable deployment at the edge, on-premise (data centers), in the cloud (private or public), or in hybrid environments and designed to meet enterprise security and privacy requirements. Software that provides manual and automate provisioning, configuration, troubleshooting, and management for the fleet of devices. Leverage pre-built Industrial IoT analytics that are customizable for rapid time to market or build your proprietary offerings. A cost-effective platform with fast time to real business outcomes.

VIMANA

Smart, connected products are transforming Industrial businesses. VIMANA provides these companies with an IoT Connected Product platform with solutions for Field Service Management, Asset Performance Management, and Remote Asset Monitoring that optimizes aftermarket service delivery and increases revenues with service-based models and offerings.