VIMANA ELEVATE: SMART MANUFACTURING ANALYTICS APPLICATION

Empower Front-Line Workers, Lean Processes, And Transform Factories With The Knowledge To Elevate Performance.

VIMANA Elevate

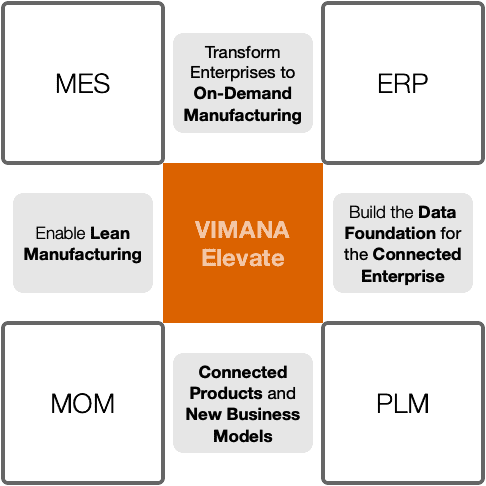

VIMANA Elevate is the next-generation Smart Manufacturing Analytics application with out-of-the-box functionality for immediate value realization. VIMANA Elevate goes beyond OEE Monitoring to true Operational Excellence, providing decision support to improve operational and financial performance. It is adaptable to heterogeneous manufacturing environments and fully customizable to an ever-expanding list of use-cases.

How VIMANA Elevates Factory Performance

Improve Plant Efficiency

Lean processes and improve standardized work practices. Reduce operating costs and CAPEX investments.

Increase asset And Line Performance

Boost factory throughput. Reduce downtime, move to predictive maintenance. Decrease cycle time and WIP inventory.

Enhance Workforce Efficiency And Safety

Remote monitoring. Optimize staffing. Adopt productivity tools to increase operator effectiveness.

Make Supply To Meet Demand

Manage disruption. Optimize profitability during volatile demand. Enable manufacturing flexibility.

Our Clients Improve Profit and Time to Market

“VIMANA’s manufacturing analytics informed process changes that increased machining profitability and shortened our NPI process.”

Elisabeth Smith, CEO

Acutec Precision Aerospace, Inc

VIMANA Elevate Capabilities

Visualize & Monitor

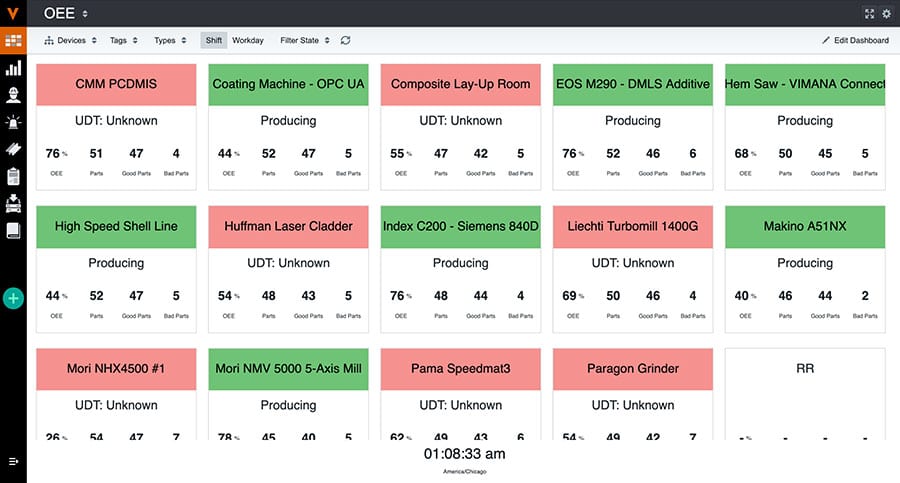

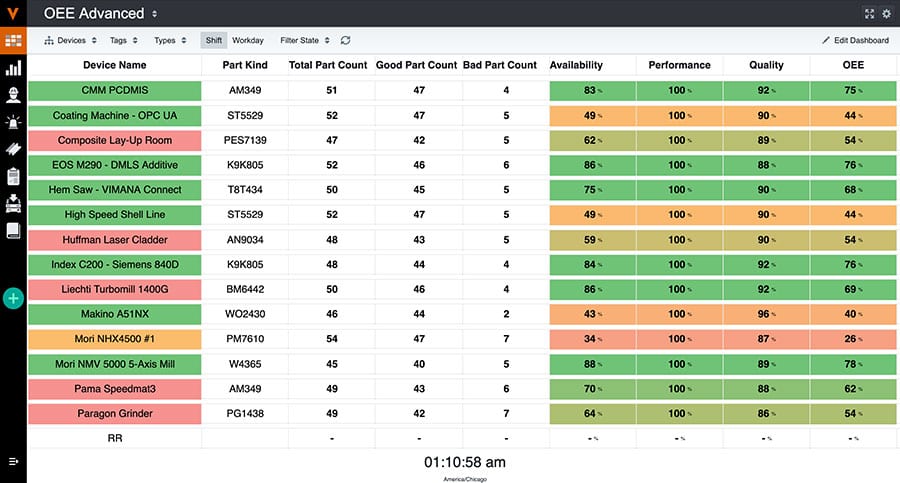

Gain insight into the status, machine health, process parameters, and part production with pre-built dashboards. Use self-serve capabilities to build custom dashboards for specific use cases.

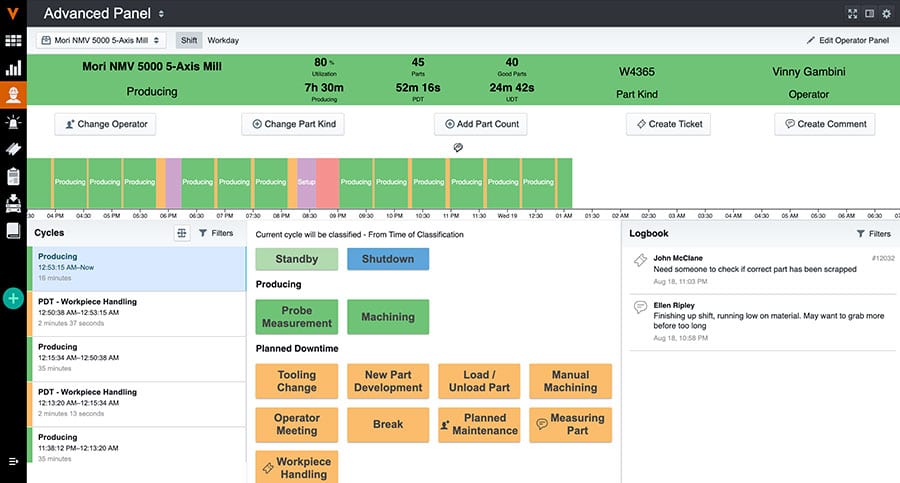

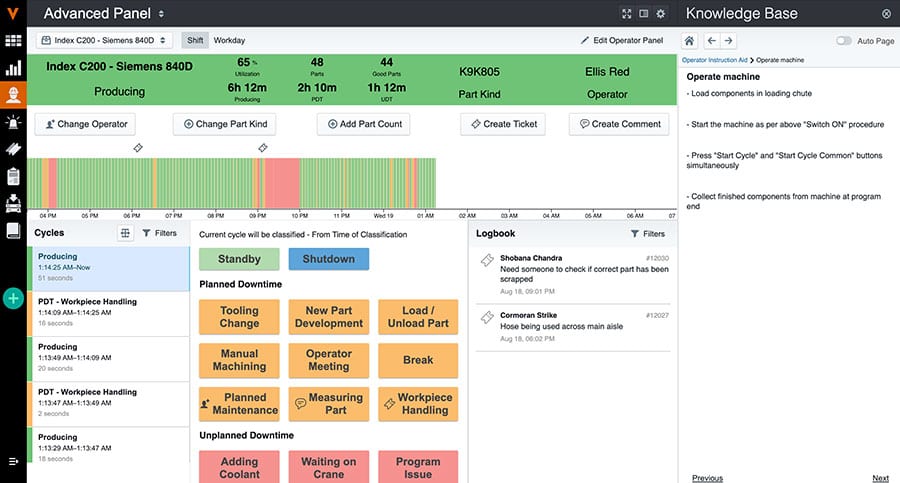

Gain insight into the status, machine health, process parameters, and part production with pre-built dashboards. Use self-serve capabilities to build custom dashboards for specific use cases. Make operators self-sufficient and more productive. The highly configurable operator interface provides information on performance and productivity tools for communications and training.

Make operators self-sufficient and more productive. The highly configurable operator interface provides information on performance and productivity tools for communications and training. Establish a baseline, monitor, and compare relevant KPIs for your stakeholders. The pre-built metrics catalog includes True OEE, utilization, lights out, part counts, and cycle time metrics.

Establish a baseline, monitor, and compare relevant KPIs for your stakeholders. The pre-built metrics catalog includes True OEE, utilization, lights out, part counts, and cycle time metrics.Analyze & Predict

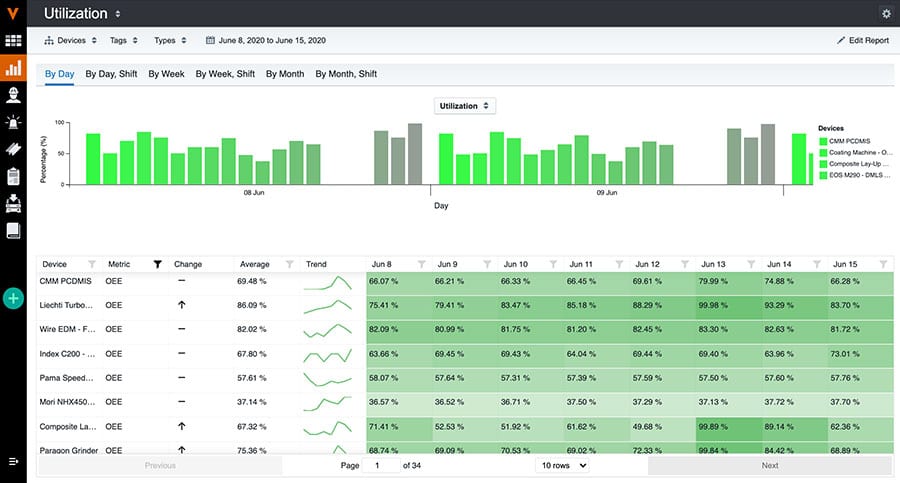

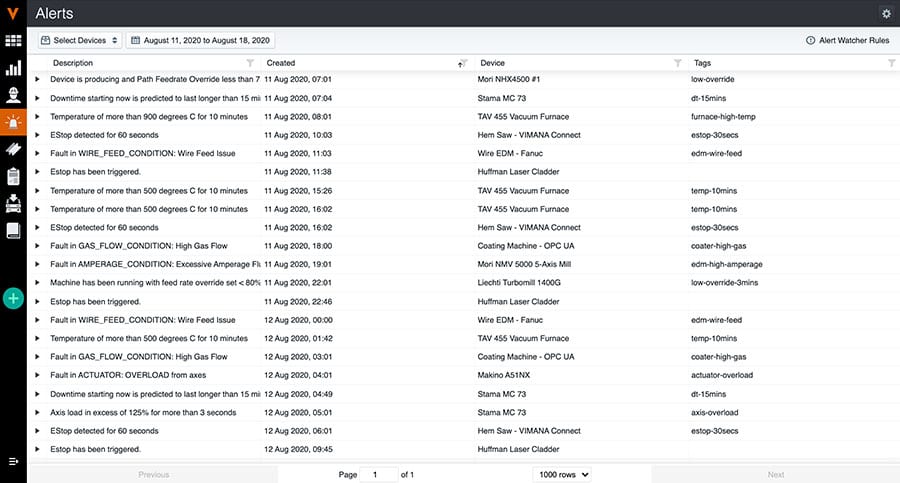

Out of the box and custom reports reveal insights into what happened, for how long, and why it happened. Identify waste. Understand trends, patterns, and production risks.

Out of the box and custom reports reveal insights into what happened, for how long, and why it happened. Identify waste. Understand trends, patterns, and production risks. Predict equipment downtimes and machine faults, tooling failures, and quality risks. Quantify measurement bias to reduce scrap and analyze tool usage for optimizing tool changes.

Predict equipment downtimes and machine faults, tooling failures, and quality risks. Quantify measurement bias to reduce scrap and analyze tool usage for optimizing tool changes.Communicate & Empower Action

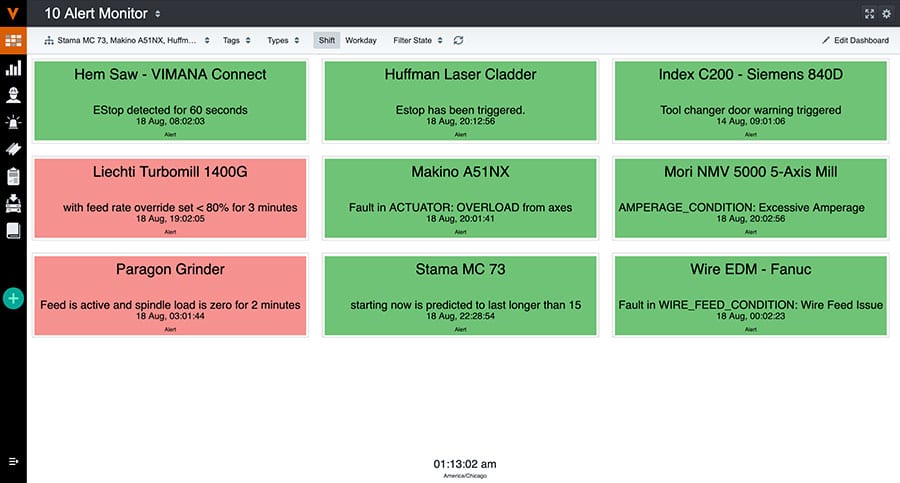

Automatically and proactively notify stakeholders in real-time to process parameters beyond established thresholds to ignite action, control performance, and manage process change.

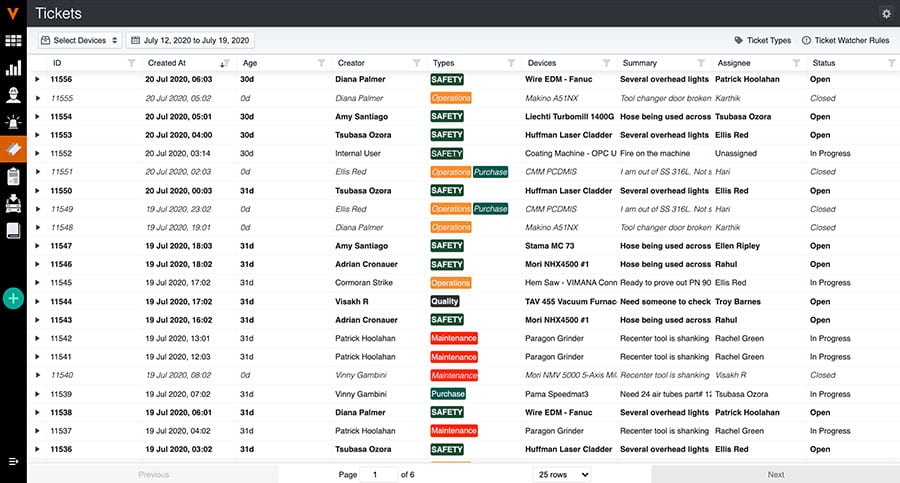

Automatically and proactively notify stakeholders in real-time to process parameters beyond established thresholds to ignite action, control performance, and manage process change. Communicate and track operational issues and requests across the workforce for rapid, closed-loop problem-solving and to inform process change.

Communicate and track operational issues and requests across the workforce for rapid, closed-loop problem-solving and to inform process change. Enables paper to digital migration, capturing the history of a workstation’s issues and comments for smooth shift handover and tribal knowledge sharing.

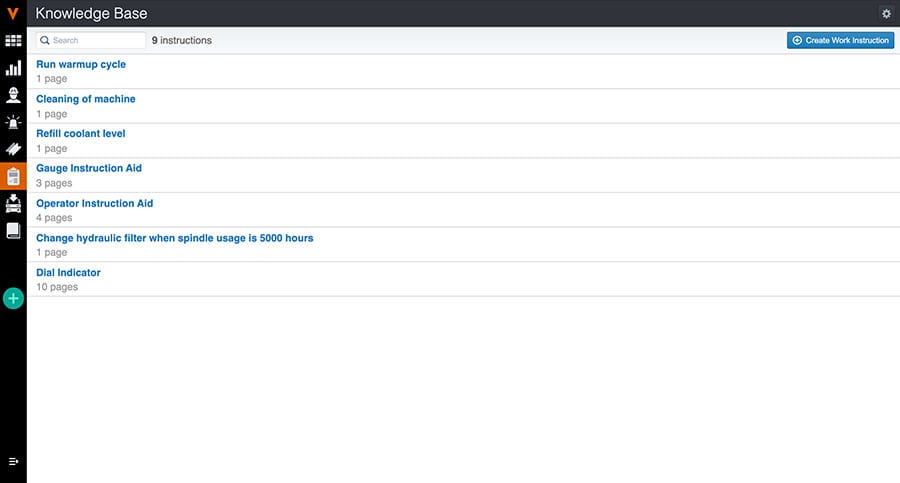

Enables paper to digital migration, capturing the history of a workstation’s issues and comments for smooth shift handover and tribal knowledge sharing. Provide device or process guidance based on activity and sequential operation to improve operator skills, reduce errors, and improve the productivity of new and existing employees.

Provide device or process guidance based on activity and sequential operation to improve operator skills, reduce errors, and improve the productivity of new and existing employees.Integrate & Automate

Use APIs and connectors to integrate with other systems (MES, ERP, APM, EAM, CMM, SCM) to streamline workflows, minimize redundancy, and automate processes.

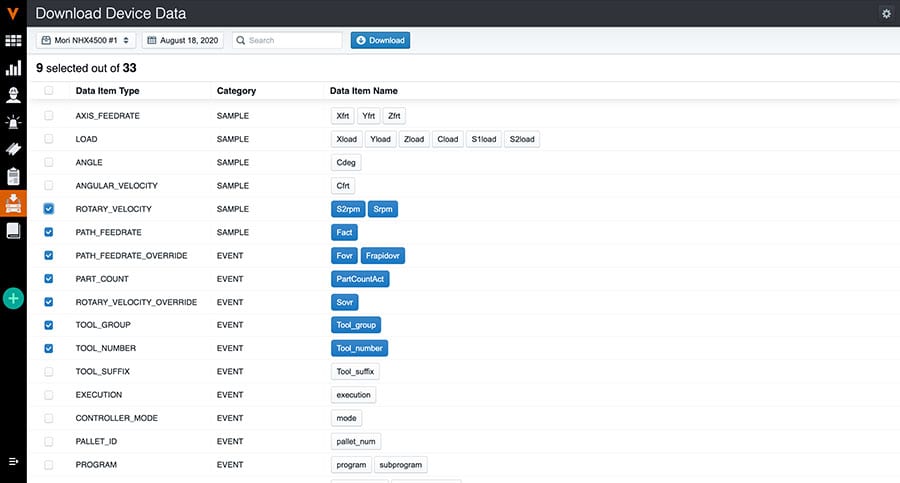

Download data for additional analyses by downstream systems (PowerBI, Tableau, Excel, SAS, etc).

Download data for additional analyses by downstream systems (PowerBI, Tableau, Excel, SAS, etc).