Industrial IoT Data Collection and Data Transformation

Essential to your Smart Manufacturing Success

Manufacturers Need Help with IoT Data Collection

Table of Contents

There is a growing demand for Smart Manufacturing analytics to innovate how large and small discrete manufactures lean processes, reduce costs, and enable resilience and flexibility in their operations post COVID.

Smart Manufacturing success depends on the data. However, manufacturers struggle with this critical step – collecting untapped data in real time from the manufacturing floor and preparing it to be consumed by advanced analytics applications.

Simply connecting sensors and capturing volumes of data does not make it usable. The data must be collected from many data sources, unified, and enriched to ensure accuracy for reliable analysis and insights. The data must be relevant to answer stakeholder questions, bring new information beyond the line of sight, and provide predictions for proactive action.

Today, more Manufacturers realize they need help with connectivity, IoT data collection, and data transformation. They ask:

- What value can I get from collecting data from IoT devices – how can it answer stakeholder questions?

- How do I build a data foundation that can be used for industrial analytics?

- How do I get my factory connected quickly?

- What is the best approach to collecting and preparing the data for analysis?

- How can VIMANA help?

Why is IoT Data Collection Important To Manufacturing?

The answer is simple: Competitive advantage; Productivity and Profitability; Resilience.

Real time data provides operational visibility to the plant and the manufacturing enterprise. Manufacturing companies can get a true understanding of their operations and make informed decisions to improve performance and be responsive to changes in customer demand. Big data reveals the information needed to improve asset and line performance, asset reliability and maintenance, workforce productivity, and lean manufacturing processes.

The Challenges in Collecting and Preparing Data

No matter the size of your manufacturing company or your approach to data-driven manufacturing, the #1 challenge remains the same: collecting, preparing, and transforming raw data to usable analytics-ready data for actionable insights. There are 5 primary challenges:

1. Variety of Data Sources, Equipment Types and Processes

Manufacturing environments are highly diverse. Factories contain a multitude of machines from different suppliers, relying on various control systems and protocols. In addition, up to 50% of the shop floor can be legacy equipment presenting connectivity and IoT data capture issues. The data is inconsistent with proprietary structures and formats, making it impossible to be used effectively for analytics.

2. High Volume and Velocity of Data

There is a large volume of data due to the increasing number of IoT sensors and connected devices (IDC predicts 41.6 billion devices connected to the internet by 2025) and the amount of data generated from each manufacturing process. Manufacturing requires high velocity data flow to deliver real time information for immediate decision making and predictive insights.

3. IoT Data Quality and Deeper Meaning

You can’t make good decisions from bad data. Big data quality relies on data accuracy, completeness, standardization, and contextualization. Data streams have no context to explain what the stream was, where it was from, what the expected tolerances were, or what the unit of measure was. You need advanced mechanisms for multi perspective relationships across different data sets to enable meaningful insights.

4. Skilled Resources to Support IoT Data Collection

Manufacturing data is not like standard business data used by IT professionals. It takes a specialized skill set with knowledge of both data science and industrial processes to support IoT data capture and transformation. Accessing skilled resources can be difficult, and sometimes, companies lack these internal skills.

5. Time to Value and Total Cost of Ownership

Building an Industrial IoT data foundation that supports data processing, advanced analytics, and flexible storage options is essential to your smart manufacturing success and can require significant investment. The total cost of ownership typically includes: incremental resources (data scientists, system integrators), new technology required i.e. data platforms and applications, and infrastructure costs (network, processing and storage). However, there are more and more disruptive technologies and services available today that will align to your needs and budget.

IoT data collection solutions can be time consuming to deploy and manage. Many manufacturers run POCs with 5-10 machines and then find it very difficult to deploy and scale quickly. Also, users can spend 80% of their time on data preparation and enrichment identifying the right data and transforming the data to analytics-ready data. Data transformation tools and vertical expertise can eliminate these problems.

Solving the Problems of Industrial IoT Connectivity, and IoT Data Collection and Transformation

How to Generate Analytics-Ready Data Efficiently

How Do I Get Industrial IoT Devices Connected?

How Do I Automate IoT Device Management?

Internet of things (IoT) device management software makes it easy and fast to onboard, configure, monitor, and scale IoT connectivity across all your sites. It simplifies troubleshooting by monitoring device details and connection status, enables security for verification of user identity and authentication, and speeds remote distribution and management of upgrades.

What is the Best Approach to Collecting the Right Data?

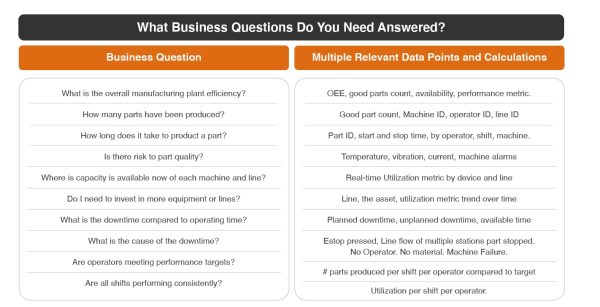

Explore the Data You Need

First, identify the key business questions you need answered. Then explore all the data points that need to be collected to address these stakeholder use cases. Sometimes one data point alone answers vital operational questions, i.e., the device location, did the machine fail, or is the furnace temperature too hot. But more often, multiple data points from multiple sources combined drive metrics, bring deeper insight, and enable future predictions.

Identify and Access All Types of Industrial Data Sources

Many data sources are needed to inform manufacturing and supply chain stakeholders. Here are a few examples.

- Machines deliver the most critical asset performance insight from new and legacy industrial equipment to include: CNCs, EDMs, additive equipment, welders, heaters and furnaces, as well as, CMM equipment, automated robots, material handling equipment, and shop floor vehicles.

- Controllers and PLCs (Programmable Logic Controllers) provide information to measure and control manufacturing processes such as automated assembly lines, extrusion lines, paint lines, and robotics.

- IoT sensors typically provide just a few data elements but are inexpensive and easy to implement. Sensors collect data from assets and process conditions (pressure, temperature, humidity, vibration, location, voltage, current, power and energy).

- Operators can add context to machine data and manual station processes to track performance and explain the “why” behind downtimes, scrap parts, and long cycle times.

- Connected manufacturing and enterprise systems add layers of context, create better understanding, and give a complete view of processes. Some examples are historians, OPC servers, DCS, SCADA, MES, CMMS/EAMS, and ERP systems.

Preparing and Transferring Machine Data

Moving Data at Real Time Speed

Industrial IoT data is of high volume and velocity. Techniques for transferring data should be selected based on time criticality, accuracy, use cases, and energy consumption. Streaming data, using standard communications protocols, is the best way to move big data at real time speeds from IoT devices to IoT gateway servers and then to the cloud for data processing and storage. This also ensures access to all data generated by each IoT device.

- Typical protocols for real time data exchange between plant IoT devices, PLCs, SCADA systems to edge servers include: OPC UA/DA, EthernetIP, Modbus etc.,

- HTTP and MQTT are typically used for sending large volumes of data from IoT Gateway servers to the cloud.

Standardizing Data With Industrial Protocols

Once the raw data is transferred from the IoT device and collected at the gateway server, transformation begins. Today, OPC UA and MTConnect have become the standard protocols for easy connection to disparate sources and data standardization from industrial automation devices and systems.

- OPC UA is based on client server communications that makes data available from industrial automation devices and systems with open device connectivity, information integration and interoperability, and security.

- MTConnect, is an open-source standard used by 300+ machine tool builders, controllers, and robotics equipment providers for machine data. It also provides domain-specific data dictionaries and models (OPC UA does not), to standardize device data across different machine types and vendors. MTConnect Adapters convert the machine’s proprietary data to MTConnect. MTConnect is extensible, and integrates with other standards, like OPC UA, by design. MTConnect and OPC UA interoperability specifications define the data exchange between the two standards. By applying the MTConnect semantic data model to OPC UA, connectivity and interoperability is significantly increased. Critical manufacturing information needs both semantic definitions from MTConnect and the protocol and security features of OPC UA.

- Sensors and digital and analog I/O adapters with Ethernet are typically used to extract the necessary signals from the legacy machines that lack connectivity for IoT data collection.

Make the Data More Useful with Data Enrichment

Once the raw data is cleaned and structured, it can be enriched with relevant context obtained from additional sources (Sensors, MES, ERP, SCADA or other databases). Data enrichment makes the data more useful and insightful by adding value to it. Enhanced data is what is needed to power advanced analytics to answer your most pressing business questions. It enables manufacturers to understand the true state of devices and manufacturing processes.

The VIMANA Approach to Automating IoT Data Collection and Transformation

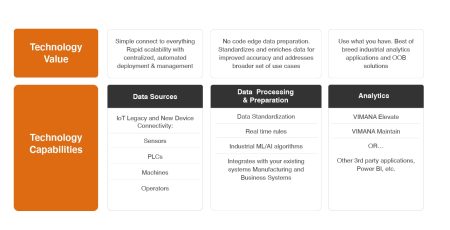

VIMANA’s cutting edge technology adds value to your existing technology investments. We ensure the data is usable quickly and cost efficiently.

VIMANA’s Cutting Edge Technology Prepares Analytics-Ready Data

VIMANA Delivers Value Based Services to Ensure Success

Discrete manufacturing vertical industry knowledge. VIMANA’s data standards experience powers relevant data discovery and data preparation for real business outcomes. VIMANA’s co-founders architected the MTConnect standard and OPC/UA – MT Connect Interoperability specification. The VIMANA team offers deep expertise in manufacturing processes and technology.

Discrete manufacturing vertical industry knowledge. VIMANA’s data standards experience powers relevant data discovery and data preparation for real business outcomes. VIMANA’s co-founders architected the MTConnect standard and OPC/UA – MT Connect Interoperability specification. The VIMANA team offers deep expertise in manufacturing processes and technology.

Discrete manufacturing vertical industry knowledge. VIMANA’s data standards experience powers relevant data discovery and data preparation for real business outcomes. VIMANA’s co-founders architected the MTConnect standard and OPC/UA – MT Connect Interoperability specification. The VIMANA team offers deep expertise in manufacturing processes and technology. End to end services available. VIMANA’s users don’t need incremental resources to support IoT data collection. We make the data work to answer your business questions from connectivity to insights.

End to end services available. VIMANA’s users don’t need incremental resources to support IoT data collection. We make the data work to answer your business questions from connectivity to insights.

Rapid Time to Value and ROI, at Low Total Cost of Ownership

Flexible consumption of the software. VIMANA’s ‘composable’ software solution, enables you to purchase just what you need. VIMANA’s data can be consumed by any 3rd party downstream analytics solution and is not reliant on the use of VIMANA’s smart manufacturing applications.

Flexible consumption of the software. VIMANA’s ‘composable’ software solution, enables you to purchase just what you need. VIMANA’s data can be consumed by any 3rd party downstream analytics solution and is not reliant on the use of VIMANA’s smart manufacturing applications. Agnostic deployment and integration with existing systems. VIMANA enables your ecosystem from shop floor IoT devices, integrations with systems and platforms, to data storage and management. VIMANA fits into your environment on-prem, hybrid, or in the cloud.

Agnostic deployment and integration with existing systems. VIMANA enables your ecosystem from shop floor IoT devices, integrations with systems and platforms, to data storage and management. VIMANA fits into your environment on-prem, hybrid, or in the cloud.