Transforming Your Manufacturing Operation

Begins with Monitoring Your Machines and Measuring OEE

Automate real-time data collection and get visibility into your machines and manufacturing facilities.

Monitor, analyze, and improve production capacity, machine uptime, cycle time, and product quality.

FREE PRODUCTION ASSESSMENT

"*" indicates required fields

Understand How VIMANA Can Help You

Increase visibility to your operation to include machines, lines, and worker productivity.

Monitor, analyze, and predict machine performance and health.

Measure, standardize, and track OEE and other critical machine and manufacturing KPIs.

Communicate and empower workers with data-driven insights to improve processes and performance.

Understand root causes of bottlenecks and waste to guide continuous improvement.

Global Discrete Manufacturers of all Sizes Trust VIMANA

VIMANA’s Machine Monitoring software improved machine utilization and increased capacity by 20%.

“We are using VIMANA Elevate, smart manufacturing analytics, to make decisions and improve awareness across the facility. Our operators have welcomed the objective data, and we are fully transparent with the analytics”.

Elisabeth Smith,

President & CEO, Acutec Precision Aerospace, Inc.

Watch a 2 Minute Demo

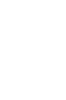

Quickly Connect and Collect Machine Data From Anywhere

Get you shop floor connected in a day. Use VIMANA’s automated data collection software to capture data from sensors, systems, employees, and machines (using standard protocols (MTConnect, OPC UA).

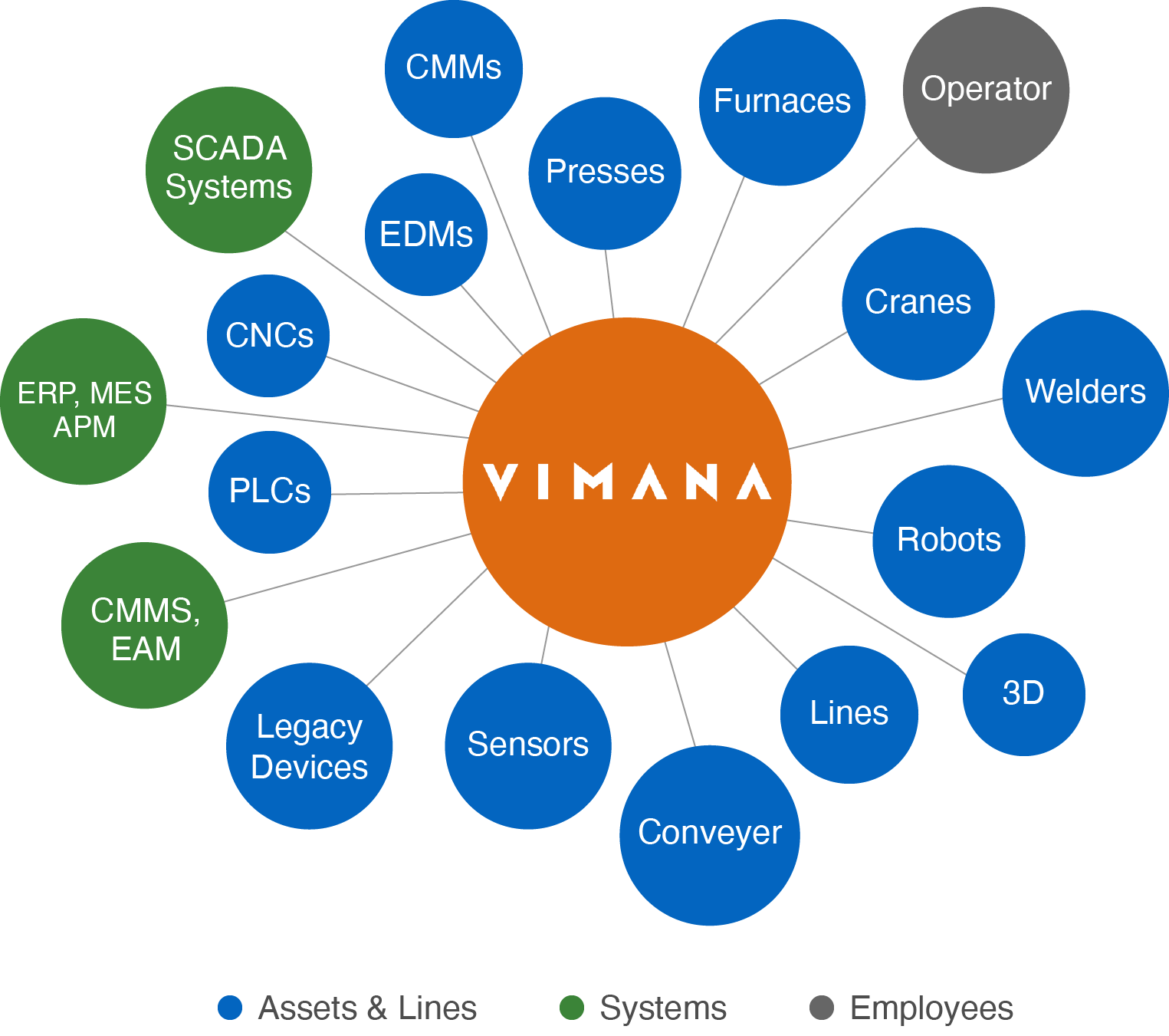

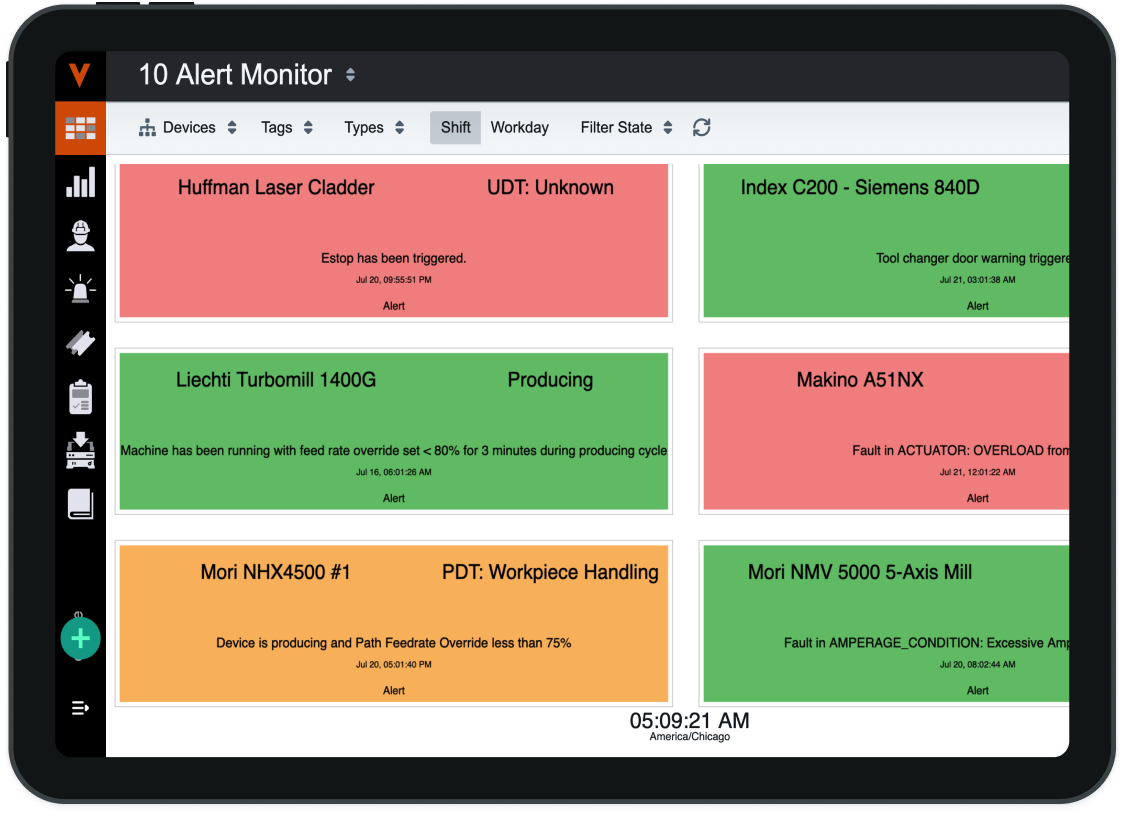

Visualize and Monitor Machine Performance Remotely

Easily access and customize pre-built Dashboards, Reports, and Alerts without coding for rapid time to value. Get real-time, accurate OEE measurements revealing all elements of the OEE calculation: asset availability, cycle time, and quality metrics.

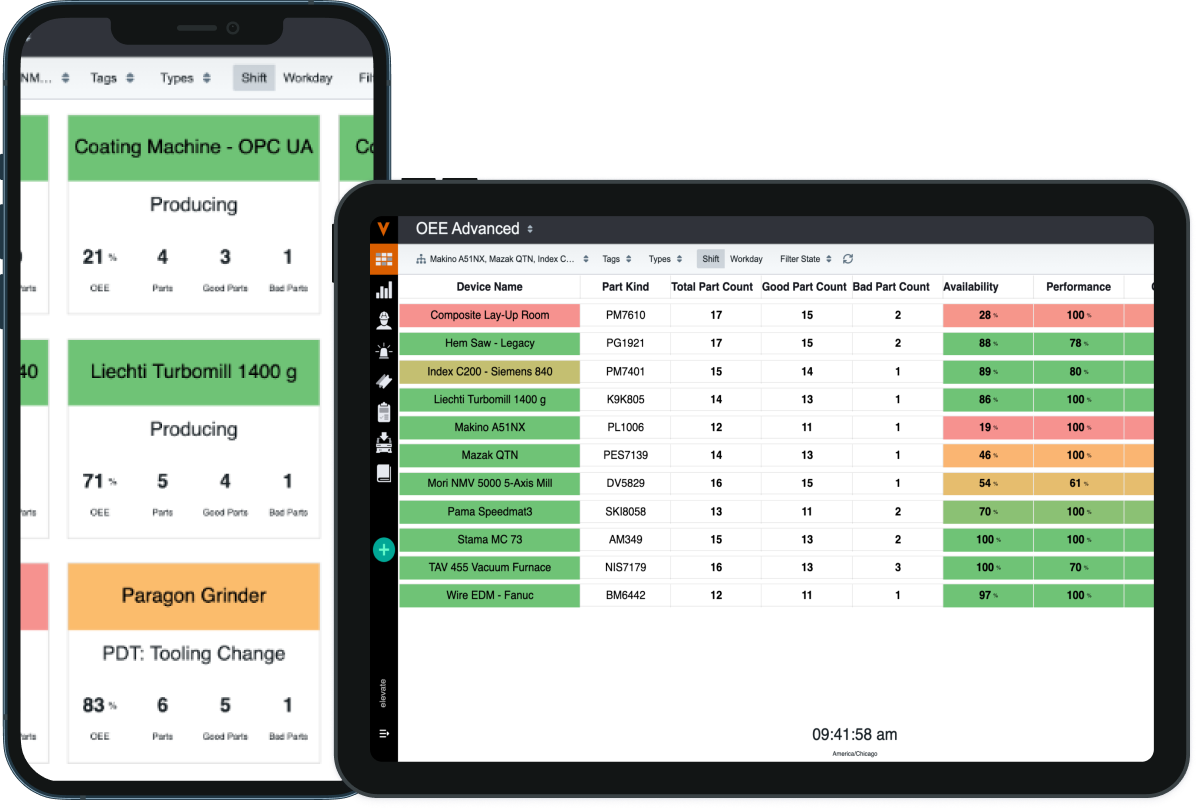

Analyze and Predict Performance

Get insights into waste and root causes. Diagnose and predict machine downtime and maintenance problems. Use condition monitoring to identify machines operating beyond expected thresholds and predict machine performance or product quality risks.

Communicate and Take Proactive Action to Lean Processes

Start Improving your Manufacturing Operation Today