Why Implement a Predictive Maintenance Strategy?

Improve Asset Availability While Reducing Costs

Table of Contents

What Does Predictive Maintenance Mean?

Predictive Maintenance Definition

Manufacturers and software providers define ‘Predictive Maintenance’ as the proactive maintenance strategy that uses big data and analytics to prioritize and optimize asset maintenance.

Predictive maintenance relies on real-time IoT data and analysis to monitor usage patterns and detect anomalies in the actual operating condition of equipment, predicting upcoming failures or loss of efficiency, and maximizing the availability of the asset. With predictive maintenance, maintenance activities are scheduled as needed, reducing unnecessary repairs and the negative impact of maintenance operations on the profitability of the manufacturing plant.

Predictive Maintenance (PdM) promises the innovation of maintenance processes to eliminate waste, reduce operational costs, and ensure high asset availability. It replaces the manual and labor-intensive repair lifecycle using reactive maintenance and calendar-driven preventive maintenance

From Reactive Maintenance to Proactive Maintenance

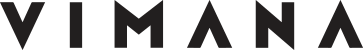

In general, maintenance falls into two categories: reactive and proactive. Reactive maintenance triggers repair when equipment failure occurs.

Proactive maintenance or Preventive maintenance, focuses on avoiding repairs and asset failure through preventive methods, replacing or restoring worn components before performance degradation or failure.

Preventive maintenance (PM) is typically determined by triggers such as time, usage, or conditions. Preventive maintenance evolves to predictive maintenance when these triggers and thresholds are defined using IoT-powered analytical techniques as opposed to empirical observations. Predictive maintenance includes usage and condition-based maintenance, as well as fully autonomous approaches, that are completely driven by learning from past failures.

Different Types of Maintenance Strategies

Optimizing maintenance performance depends on making smart and strategic decisions about which assets need maintenance and when. There is no one strategy but instead requires a continuum of maintenance strategies from reactive to autonomous predictive maintenance. Maintenance teams need to choose the right strategy for each asset type, level of production risk, and cost implication.

Reactive Maintenance

This approach is run to fail, then repair. An analogy is to repair a car radio when it breaks. This results in high unplanned downtime, production disruption, and increased costs. This is best implemented when there is redundant equipment and the cost of repair is the same as breakdown.

Time-Based Maintenance

Maintenance is performed at predetermined calendarized intervals, regardless of whether maintenance is needed. An analogy is performing an annual tire rotation. The typical use case is assets with constant usage and predictive linear degradation or the requirement to comply with OEM service contracts. Purely time-based preventive maintenance increases unnecessary maintenance and spare parts inventory.

Use Based Maintenance

Condition Based Maintenance

This is a proactive maintenance approach where tasks are performed when parameters reach unacceptable levels, indicating imminent breakdown. An analogy is monitoring car oil pressure and coolant temperature to trigger maintenance when indicators are beyond acceptable thresholds. CbM relies on sensors (example: pressure, temperature, vibration), real-time equipment monitoring, and analysis to compare current conditions to normal behavior, revealing abnormalities that can trigger maintenance actions. This requires baselines of normal behavior with historical information and tribal knowledge. CbM is best used for assets that have well-known failure modes, and conditions are a proxy for problems.

Autonomous Predictive Maintenance

Autonomous Predictive Maintenance operates without human involvement. It builds on the previous 2 strategies (UbM and CbM) and relies on volumes of operational and process data, precise multivariable algorithms, and machine learning to identify the relevant conditions and associated baselines for equipment degradation. Analytics tools and techniques automatically identify failure mode, compute risk scores, and prioritize early warnings for assets at risk. Algorithms are trained using historical usage and failure data and estimate the probability and impact of failure and when it will occur. Work is scheduled in the future and determined by analytics. The best use case is for critical assets where stoppages have a substantial operational impact and where adequate historical data is available.

Why is Predictive Maintenance Important?

Why Change Your Current Maintenance Strategy

Change depends on your answers to the following questions:

- Is your maintenance organization running at peak efficiency?

- Are you struggling to meet performance targets: OEE, MTBF, MTTR?

- Are you meeting maintenance cost and budget objectives?

- Do you need to do more with fewer maintenance resources?

- Are you having difficulty managing backlogs of reactive and scheduled maintenance activities?

- Is it challenging to determine staffing needs and schedules?

- Has production missed delivery dates due to critical asset downtime? Are there part quality issues due to equipment and tool failures?

- Is it resource intensive to collect the data you need to drive maintenance process improvement?

Predictive Maintenance Benefits

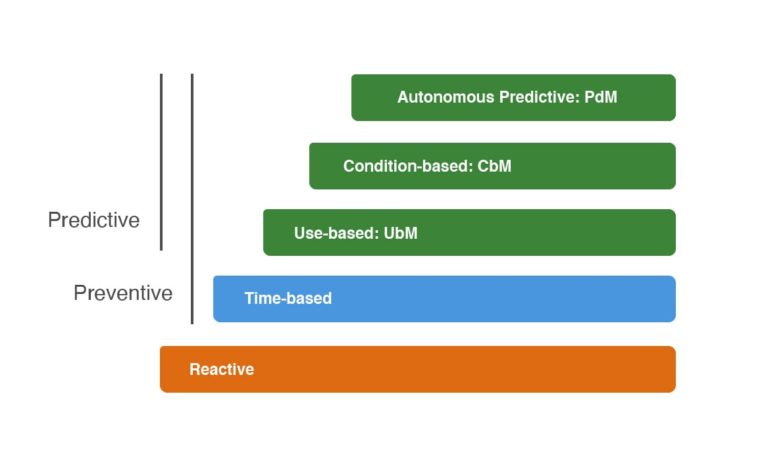

Boost Asset Availability, Flexibility, and Reduce Downtime.

Incorrectly planned maintenance practices can limit production availability. Predictive maintenance programs provide the intelligence to prevent failures, reduce hours spent prematurely maintaining equipment, and optimize parts replacement. They help reduce disruptions of mission-critical equipment and system-wide production service loss. Plant repairs can be performed when it’s convenient for production, ensuring assets are available when needed.

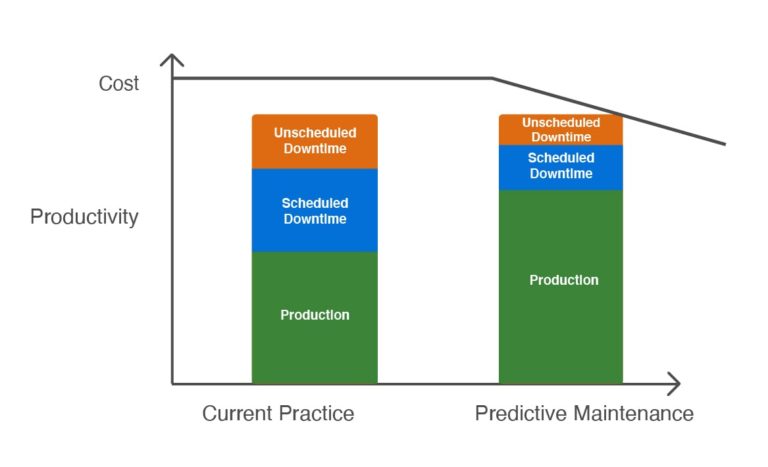

Reduce Maintenance Costs by 18-25%. Improve CAPEX Decision Making.

Depending on the industry, maintenance costs represent between 15-60% of the costs of goods produced, with industrial manufacturers at the high end. Moving to proactive and ultimately predictive maintenance approaches reduces the labor costs as well as technician overtime and contract labor.

Further cost reductions can be realized by optimizing the inventory of spare parts and tooling – parts can be replaced only when failure is imminent, allowing just-in-time inventory management. The yield of consumables can be increased with preventative maintenance driven by asset usage/conditions vs. calendarized scheduling.

By reducing maintenance-driven disruptions, the hidden costs of poor maintenance that contribute to profit risks can also be mitigated – late delivery, quality spills, high scrap, safety risks, and excessive planning resources.

Finally, robust predictive maintenance strategies can reduce capex with smart investments. Bain & Company stated that Industrial Company’s cut R&D and CAPEX investments by 60% in 2020 to conserve cash and contain costs. Historical machine information enables better investment decisions regarding the maintenance to extend asset life vs. replacing equipment.

Improve Maintenance Workforce Productivity and Effectiveness.

Moving away from reactive maintenance can help in optimizing the planning and scheduling of maintenance team resources. Analytics enables the proactive, intelligent planning of technicians and part availability.

Data-driven insights can also help reduce MTTR by improving problem diagnosis. Understanding when the failure occurred, the casuals, the preceding faults and conditions, parts produced, prior equipment performance, the tooling used, and equipment operator can enable accurate, quick problem diagnosis.

Workforce productivity can be further improved by automating workflows by integrating maintenance analytics with CMMS and EAM systems. Digital operator and incident management tools can generate alerts for the maintenance team for issues that require resolution, while providing two-way communication.

Why Change Now to Predictive Maintenance?

Predictive maintenance was originally applied in asset-heavy industries such as Oil and Gas, but the advent of cost effective Industrial IoT Analytics platforms has brought predictive analytics to the manufacturing industry. This is being powered by several technology trends – the proliferation of sensors, cloud computing, big data tools, advanced analytics, and ML/AI algorithms – that are making predictive analytics technology more accessible across new domains.

Manufacturing is also transitioning away from reactive maintenance due to cost and capacity pressures, making it imperative for plants to adopt preventive and ultimately predictive techniques to be competitive.

The COVID19 crisis and ‘new normal’ business drivers are accelerating digital transformation. Maintenance teams need to automate manual and inefficient processes to increase flexibility and resiliency. Advanced analytics provides intelligence to do more with less, ensure critical asset reliability, and support on-demand manufacturing requirements.

Predictive Maintenance Examples

Turbine Manufacturer Implements Use Based Maintenance for Costs Savings

- The Solution: This factory monitors and analyzes spindle usage and axes movement data displaying real-time dashboards of usage hours and the remaining useful life which dictates the next PM. When the asset reaches the defined threshold, the system triggers preventive maintenance work order in their EAM system. This resulted in fewer PMs, saving labor and PM kit material costs totaling 25% of their total plant maintenance spend for the year.

Machine Tool Manufacturer Uses Condition Monitoring For Remote Service

- The Solution: Historical machine faults and warnings are analyzed for trends and patterns to gain insight into high probability failure risks with the associated root casuals. This helps the customer support team diagnose equipment issues. Critical conditions are prioritized and automatically trigger a work order in their CMMS to dispatch an on-site technician. This resulted in improved remote services delivery and effectiveness of on-site visits.

Rotating Machinery Manufacturers use Vibration Analysis for Equipment Diagnosis

- The Solution: Vibration analysis allows technicians to monitor machine vibration patterns from equipment sensors. Technicians can compare the readings against known failure modes to determine where problems are occurring. This information triggers proactive repair and replacement of components like bearings and shafts and increased technician productivity.

Industrial Manufacturer uses Condition Monitoring and Oil Analysis to Optimize Maintenance Planning and Scheduling.

- The Solution: The manufacturer uses Oil analysis to determine if contaminants are present. Using the machine’s Oil analysis as a baseline they augmented the analysis by integrating additional conditions and utilization data to ensure problem diagnosis and prediction accuracy. The maintenance team optimized their preventive maintenance schedules, reduced material, and labor costs while increasing equipment availability.

How Does Predictive Maintenance Work?

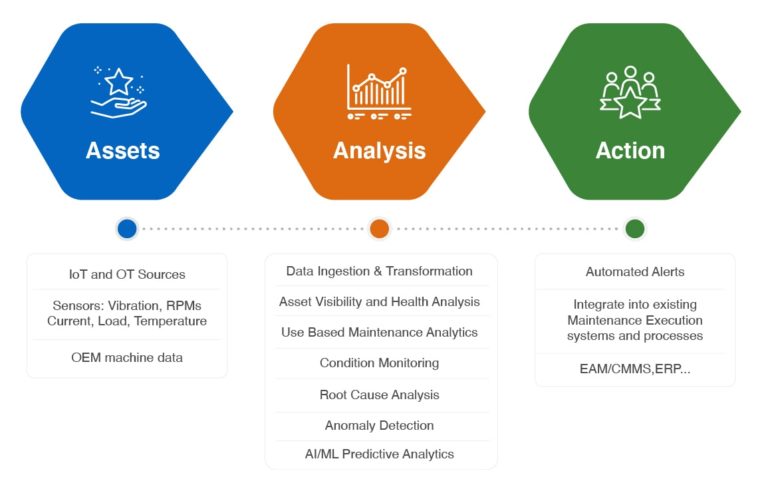

Assets

Predictive Maintenance begins with Asset data – this includes process and health parameters, for example: electrical currents, vibrations, temperature, humidity, torque, load, axes position, rotation, spindle speed, pressure. Collect the data from the various OT and IT sources, including: sensors, machine data, PLCs, robots, 3D printers, manual stations, historians, SCADA, CMMS, EAM, and ERP systems leveraging open standards (MTConnect, OPC UA) and proprietary protocols. Contextualize the manufacturing and enterprise data leveraging machine learning to ensure data uniformity, integrity, enabling a broad array of use cases and stakeholders. Most importantly, transform your data into an enriched analytics-ready scalable data foundation, generating production metrics, condition parameters usage meters, part information, operator ID, job numbers, and other KPIs that can be used for analysis.

Rapidly deploy and scale effortlessly with automated device connectivity and configurability across globally connected plants, suppliers, and customers.

Analysis

Asset Visibility and Health Analysis

Use Based Maintenance

Usage analytics is a reliable predictor of a malfunction vs. calendar intervals. OEM guidance on preventative maintenance typically references a timeframe and a usage parameter. Collect machine data to monitor and analyze equipment usage: machine run-time hours, miles driven, cycle counts (injection molding machines), tool usage (spindle), or parts produced to drive planning and scheduling maintenance tasks and resources. The data-driven insight will ensure the machines warrant maintenance or inspection, and that technicians have the right maintenance tools and parts to do the repairs.

Condition Monitoring

Monitor and analyze the condition of equipment to detect deterioration signs, anomalies, and equipment performance issues. Develop rules logic to trigger when parameters reach unacceptable levels. Plan maintenance work proactively aligned to performance thresholds. This will reduce unplanned downtime, production risk, and overall maintenance costs.

Root Cause Analysis

Identify and control the main causes of machine failure and problems. RCA is designed to discover what happened, why it happened, and the underlying causes. Root cause failure analysis can answer why with IoT historical data from previous failures, the frequency, duration, and causes (technical parameters or human) of the events that lead to the breakdown.

Anomaly Detection

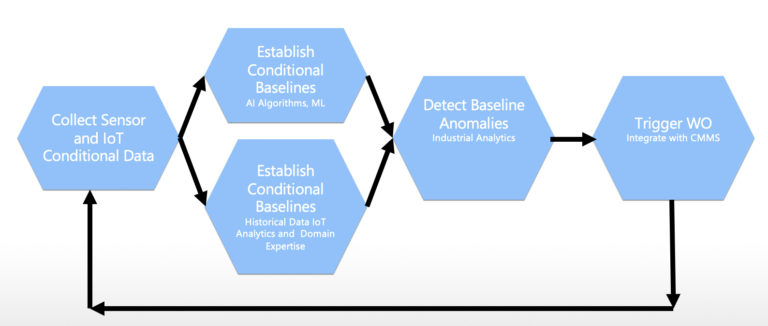

Use IoT analytics to understand patterns and deviations in equipment or component performance, unobservable to the human eye. These algorithms compare the current condition parameters to historical normal performance to find anomalies that indicate the machine is not in an optimal state and exhibiting early signs of malfunction. Anomaly detection lies at the core of PdM, detecting abnormalities, checking correlations and patterns across thousands of data feeds which is impossible using a manual approach.

Predictive Maintenance Machine Learning Models

Autonomous Predictive maintenance relies on collecting and analyzing data from various sources; sensors, equipment, and systems. Using this data, advanced ML and AI models can predict when an asset will fail and estimate its remaining useful life. Alerting the maintenance team to just-in-time repair and component replacement, only when close to breakdown. This reduces unscheduled maintenance and extends component lifespans so businesses can gain availability and dramatic cost savings. Predictive maintenance depends on volumes of high-quality, historical condition data and iterative predictive algorithms.

Action

Automate the work order process by integrating maintenance analytics with CMMS and EAM software. The usage, conditions, and predictive insights power the maintenance execution. Together these tools help companies manage their assets and people to improve asset maintenance and availability while being cost-effective.

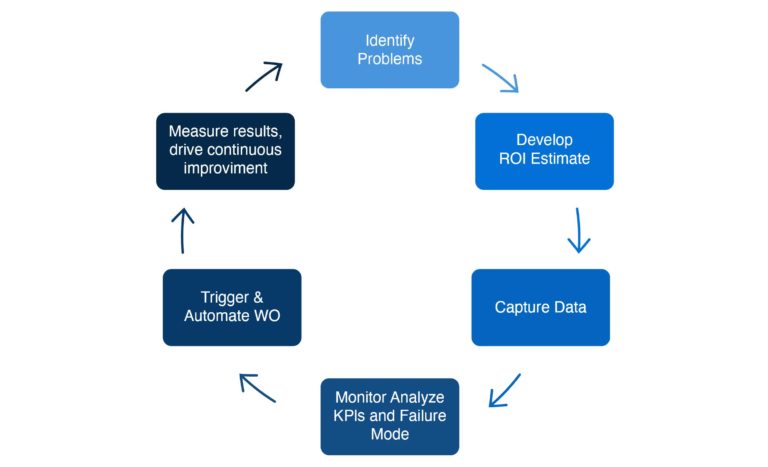

How to Create a Predictive Maintenance Program

- Identify business problems to be solved. Develop a PdM program ROI estimate. Collect information on production interruptions, equipment damage, equipment breakdown caused by higher repair vs intervention, and potential areas of waste (excessive labor and parts, waiting, inventory) to understand areas of opportunity and ROI impact.

- Capture volumes of data from sensors, machines, other sources.

- Monitor, Analyze Usage & Failure Modes. Monitor usage. Identify critical failure modes and critical condition parameters of assets, components, and sub-systems. Analyze current performance to determine baselines and thresholds. Creating alerts for usage and conditions that reach unacceptable thresholds.

- Integrate data into CMMS or EAM systems to automate work orders when trigger conditions are met. Categorize by the level of urgency to trigger when a WO should be automatically sent.

- Measure results & deliver continuous improvement of your PdM program for short and long-term value.

Summary of Predictive Maintenance Analytics

- The discrete manufacturing industry is now migrating from reactive and scheduled Preventive Maintenance to Predictive Maintenance.

- Predictive Maintenance relies on real-time IoT data and advanced analytics to optimize asset reliability and availability.

- Predictive Maintenance monitors usage patterns, equipment conditions and detects anomalies to predict quality degradation and asset failure.

- Predictive Maintenance delivers rapid RoI and business value delivering insight to improve equipment uptime, reduce emergency repairs, and deliver dramatic cost savings in labor and materials.

- Predictive Maintenance means equipment maintenance is only performed when it is required resulting in fewer PMs and optimized scheduling. Predictive Maintenance improves MTTR and maintenance workforce efficiency, diagnosing the root cause of failures.

- Align maintenance strategies: use, condition based and Predictive Maintenance by asset types, cost impact, and operational risk.

- Predictive Maintenance challenges include the large volume of data, reliance on specialized skills to develop reliable models for decision-making and investment.

- Select Predictive Maintenance software providers that have deep domain expertise to ensure reliable data and powerful predictive algorithms. Predictive Maintenance solutions can be easy to implement and cost-effective.

- Integrate Predictive Maintenance software with EAMS/CMMS systems to automate the process from insight to repair execution.

- Pilot Predictive Maintenance with a piece of equipment or the entire fleet, then scale globally.

Next Steps for Predictive Maintenance

Curious how you can get started with condition monitoring and predictive maintenance in your operations? VIMANA can help you migrate to predictive maintenance technologies and reduce maintenance costs. VIMANA makes PdM affordable and simple to implement. Get in touch with a VIMANA expert today.